Ever heard of a rock climbing “carrot” bolt? How about a “bash in”? Unless you’re an Australian rock climber, there is a good chance that the answer is “no”. As a North American climber I certainly had never heard of them, although they apprear to be similar to the “rivets” that were once popular in Yosemite valley. So I owe a debt of gratitude to Samuel May, who was good enough to send the photo below and alert me to the existence of this uniquely Australian contribution to sport climbing. In Sam’s own words:

“The famous “carrot” bolt was developed in Australia in the 50s and 60s due to the unavailability of any actual climbing gear. It consists of a hex head machine bolt, hand-filed to a taper, and pounded into an undersized hole without a hanger. The principle is the same as a drilled piton, but cheaper!”

So there you have it. You file a bolt to a taper (so it looks like a carrot, get it?). You drill a hole in the rock. You bash the carrot in the hole with a hammer until it’s tight (thus the alternative name “Bash in”). The shaft of the carrot bolt is sticking out a bit. And that’s it. That’s your pro. How the heck does that even work? Sam proceeds to explain:

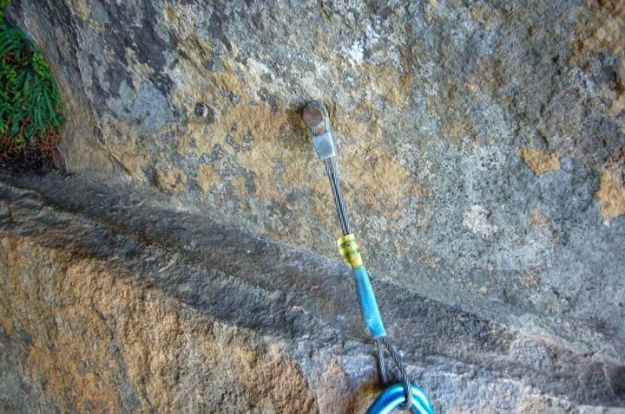

“To clip it, you either use a removable hanger (“bolt plate”) or, if you run out of those like I did at this belay on “Cave Climb” [see Sam’s photo below] in the Blue Mountains, you take a nut and slide it down the wire, slip the loop over the bolt head, and cinch the nut back up tight. You can also sling them with a skip knot on a skinny dyneema sling. Bomber!”

I trust that Sam’s use of the term “Bomber!’ is ironic, as this set up looks a bit jive-ass. So I’ve done a bit of research on my own, starting with, on Sam’s suggestion, Safer Cliffs Australia‘s website. Safer Cliffs Australia is a non-profit organization devoted to maintaining safe rock climbing areas by replacing rusty, jive-ass old bolts and anchors with safe quality ones. Here are some carrot photos from that site:

Wow, eh? Australian climbers have big balls.

So what about this ‘bolt plate’ hanger thing Sam mentioned? Here are a few photos of those:

Apparently these things are available for sale at pretty much all climbing gear shops in Australia. From what I’ve read you carry a supply of these things in your chalk bag. When you get to a bolt, you grope around in your chalk bag for a hanger plate, fish out out, and slip it over the head of the bash in carrot bolt. Then you clip a draw to it, and the carabiner, assuming it’s fat enough, keeps the hanger plate from falling off of the bolt head. And there you have it: a bolting system that gives sport climbing some of the white-knuckled, gripped thrill of trad!

Now apparently there are both zealous defenders and detractors of the carrot bolting system in Australia. So in an effort to keep myself from inadvertantly being dragged into an Aussie civil war by extolling the jive-ass qualities of this system, I think it’s worth placing this system into historical context.

Australian rock climbing pioneer and legend Bryden Allen claims to have invented the carrot bolting system some time in 1963 or 1964. I have no reason to believe this isn’t true, and I was able to find at least one resource that corroborates this claim. There weren’t exactly a lot of climbing gear options at that time. In Yosemite, for example, Royal Robbins, Yvon Chouinard, and Chuck Pratt were still putting up new routes protecting with pitons (and occasionally bolts). Royal Robbins is credited with bringing the first nuts to Yosemite from the UK in 1966. Given those conditions, the carrot bolt system, with its removable bolt plate hanger is pretty brilliant.

And with that said, here in the 21st century there now are quite a few climbing gear options–including dramatically superior bolting methods (for sport routes) and bomber spring loaded camming devices (for trad). By today’s standards, a machine bolt filed into a taper, bashed into a tiny hole and held in place through friction–especially an old and rusty one–appears a little jive-ass. Surprisingly though, from I’ve been able to determine, there aren’t many documented instances of injury or death due to bash in bolt failure.

Anyone seen this system used outside of Australia?

Location: All over Australia.

I love finding little nuggets of history halfway up a climb, things like an old piton swollen with rust give me a certain sense of constancy about the world. But I certainly wouldn’t want to rely on them.

These bolts look… interesting!

You completely missed the fun of these things: that you inevitably end up knocking one or more bolt plate off the bolts while trying to clip them, thereby running out of bolt plates earlier in the pitch than you’d expected and having to jerry rig alternative protection while stressed out later on.

And their jive-assedness is mostly to do with their variability. Modern (since the 1990s) practice has been to use stainless steel glue-in bolts rather than bash-in mild steel, and those things are bombproof (provided your bolt plate doesn’t invert and get “peeled” in a fall). But the old ones are a complete crap shoot – from failing at less than body weight to being basically as strong as glue-in stainless. As an aside, I wish more US bolters used glue-in stainless installed from abseil instead of jive-ass expansion bolts in jive-ass hand-drilled holes drilled from jive-ass stances while on pseudo (hook assisted) lead. I’ve seen way more jive-ass manky bolting here than I ever saw back home, even on modern routes.

Oh and one of the big advantages of “carrots” is that they’re nowhere near as visually apparent as ring bolts or fixed hangers, which is a big deal when much of Australia’s climbing is in National Parks (where “installations” are illegal).

Hey pmonks, I guess dropping and subsequently running out of bolt plates may explain Sam’s original wire nut placement in the post. Sounds like scary good fun!

Steve

I’ve seen these on Catharsis on Poko in the Adirondacks, NY. Don’t we just call these rivets in North America? There pretty common on big wall routes as well and you can buy rivet hangers.

Brenden has it. Bigwallers in Yosemite and beyond have been using rivets for progression and or anchors for quite some time and continue to use them today. (Heck, Native Son has the “Machine Head Wall” pitch referring to the rivet ladder on the pitch made of these machine heads)

Obviously, a proper bolt is preferable, but when hand-drilling due to wilderness laws against powered drills, the difference in effort and time it takes to drill a rivet hole 1/4″diameter x 1/2″-1″ depth versus a bolt hole 3/8″diameter x 2+”depth on longer bolt ladder sections of rock, rivets start to shine as much as the sweat dripping down your forehead beneath your helmet.

Common rivets are 5/16″ machine heads, stainless. 1/4″ splitshaft buttonheads are also used but will be called bolts rather than rivets.

These will catch longish fall most of the time, but are usually considered suspect by aid climbers as they’re placed for progression, not necessarily for protection anymore.

I’ve come across bigwall anchors made of nothing but machine head rivets and I’d say that “jive ass” was synonymous to what I was thinking at the time.

Here’s some shots from a bigwall route on Washington Column called “Horni-Johnson A3+” where the anchors at the top of pitch 3 and pitch 4 were only rivets with hangers on them.

Pitch 3 anchor: https://lh6.googleusercontent.com/-srG4gt1dBjk/USG7vgryQmI/AAAAAAAAH5E/tFivoBLaSAI/s640/photo%25201.JPG

Pitch 4 anchor: https://lh5.googleusercontent.com/-0IVa7lJrsVs/USG7vMFPdjI/AAAAAAAAH5A/caLQUTse6AM/s640/DSC02535.JPG

Brendan, carrots are similar to rivets, only usually less jive-ass as they’re either 10mm glue-in stainless (0% jive-ass) or 3/8″ mild steel bashies (variable jive-assedness, but best assumed to be jive-ass). The rivets I’ve seen (note: mostly in California) have all been 1/4″ rusted-to-crap mild steel (100% jive-ass).

Pingback: Crag Profile: Glenreagh – Zen and the Art of Climbing